Vital Insights Into Occupational Health Risks in the Artificial Stone Industry

July 30, 2024

Understanding the Differences Between Artificial Stone-Induced Silicosis and Idiopathic Pulmonary Fibrosis

August 9, 2024Blog

Exploring the Emissions and Silica Content in Stone Grinding Dust

In the evolving world of occupational health, the study of airborne particles and their effects continues to be critical, especially in industries involving stone grinding. A notable contribution to this field is the research conducted by Drew Thompson and Chaolong Qi, documented in the Oxford University Press for The British Occupational Hygiene Society. Their study meticulously characterizes the emissions and crystalline silica content of airborne dust from grinding both natural and engineered stone products.

The Study’s Context and Methodology

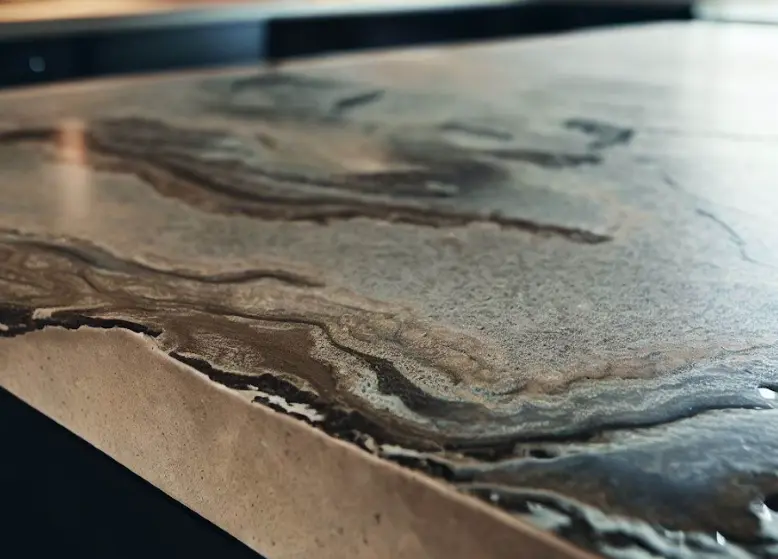

The focus on engineered stones is timely; these materials often contain high levels of crystalline silica, which can pose significant health risks to workers. Engineered stones are used primarily in countertops and can contain more than 90% silica. The high silica content is a significant concern because inhaling crystalline silica particles can lead to silicosis, a debilitating and sometimes fatal lung disease.

Thompson and Qi's study, carried out at the Centers for Disease Control and Prevention’s National Institute for Occupational Safety and Health, examines four types of stone samples—two types of engineered stones with high silica content, one engineered stone with recycled glass, and one natural granite stone. The methodology involved grinding these stones in a controlled laboratory setting to measure the dust generated, which was then analyzed for silica content using advanced techniques like x-ray diffraction and gravimetric analysis.

Key Findings

One of the crucial findings of the study is that all stone types produced similar trimodal lognormal number-weighted particle size distributions, indicating a consistency in the dust formation process across different stone types. However, the silica content varied significantly:

- Stone A, made with a polyester resin matrix, had the highest crystalline silica content, up to 90%.

- Stone B, also using a polyester resin but with reduced silica content, had about 50% crystalline silica.

- The engineered stone containing recycled glass (Stone C) showed no crystalline silica, demonstrating its potential as a safer alternative in the industry.

These findings underscore the potential risks associated with different stone types, particularly those with high silica contents. Notably, the study found that granite, while natural, still generated significant amounts of dust and crystalline silica, though less than Stone A.

Implications for Occupational Health

The research by Thompson and Qi offers substantial insights into the occupational exposure risks of different stone grinding activities. Their work suggests that while engineered stones with lower silica content (like Stone B) and alternatives like recycled glass (Stone C) can reduce health risks, traditional granite remains a concern due to its silica content.

This study highlights the importance of using adequate dust control measures and personal protective equipment (PPE) in workplaces where stone grinding is performed. Additionally, the findings advocate for ongoing monitoring and regulation of silica dust in the workplace to prevent silicosis and other respiratory diseases associated with silica exposure.

Moving Forward

The findings from this study provide a scientific basis for developing more effective engineering controls and workplace safety regulations to protect workers from silica dust. By understanding the specific conditions under which crystalline silica is released, employers can better implement strategies to mitigate exposure. These might include using wet grinding processes, improving ventilation, and using respirators.

Moreover, the study supports the innovation of safer materials, like the engineered stone with recycled glass, which do not compromise the health of workers. These alternatives could revolutionize the industry and significantly reduce the incidence of silicosis among workers.

Conclusion

The meticulous work by Drew Thompson and Chaolong Qi not only advances our understanding of the risks associated with stone grinding but also paves the way for safer industrial practices and materials. As the demand for engineered stone products continues to grow, ensuring the safety of workers must remain a priority. This study is a step forward in protecting workers from the long-term health risks associated with airborne silica.